Sliding support bearings

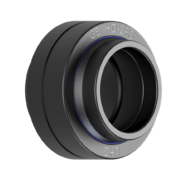

Ready-to-install and maintenance-free sliding support bearing, floating bearing and fixed point

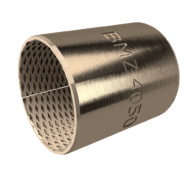

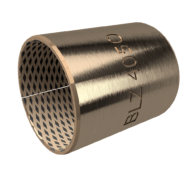

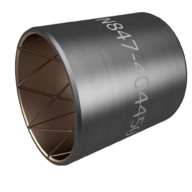

Wrapped composite plain bearing steel / PTFE coated | Maintenance-free dry plain bearing | DIN 1494 / ISO 3547

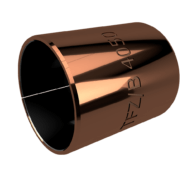

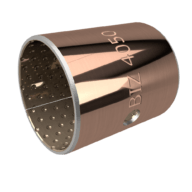

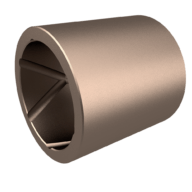

Wrapped composite sliding bearing Bronze / PTFE coated | Maintenance-free dry sliding bearing | DIN 1494 / ISO 3547 | Corrosion resistance | Anti-magnetic

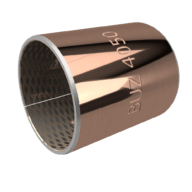

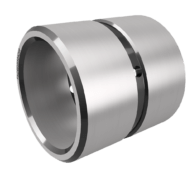

Wrapped composite sliding bearing Stainless steel / PTFE coated | Maintenance-free dry sliding bearing | Corrosion resistance | Chemical resistance | DIN 1494 / ISO 3547

Wrapped composite sliding bearing steel / Special PTFE coated | Maintenance-free dry sliding bearing | DIN 1494 / ISO 3547

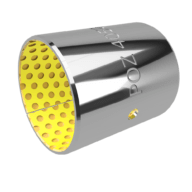

POM-MET® is a low-maintenance composite sliding bearing with a POM coating. Initial lubrication is required. Both oil or grease lubrication are possible. Due to the lubricant pockets, relubrication intervals are significantly reduced! Suitable for all sliding movements, good load capacity, robust and resistant to dirt.

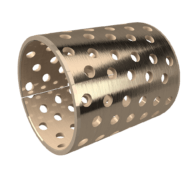

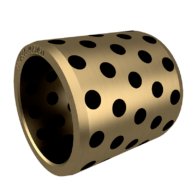

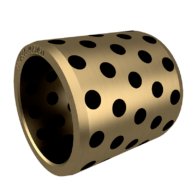

Wrapped bronze sliding bearing with lubrication pockets/ CuSn8P (DIN 17662) | Low-maintenance | DIN 1494 / ISO 3547

Wrapped bronze sliding bearing with lubrication holes/ CuSn8P (DIN 17662) | Low-maintenance | DIN 1494 / ISO 3547

Wrapped composite sliding bearing with lubrication pockets/ CuSn8P & graphite | maintenance-free | DIN 1494 / ISO 3547

Wrapped composite sliding bearing with lubrication pockets/ copper-plated steel & CuSn10Pb10 | Low-maintenance | DIN 1494 / ISO 3547

Wrapped composite sliding bearing with lubrication pockets/ copper-plated steel & CuSn10Pb10 & graphite | maintenance-free | DIN 1494 / ISO 3547

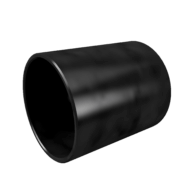

Plastic plain bearing | Maintenance-free | ISO 3547

Maintenance-free and maintenance-required

maintenance-free and maintenance-bound

Fibre-reinforced compound sliding bearing in wound technology | Maintenance-free | Highly resilient

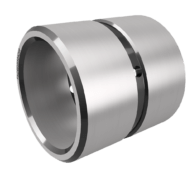

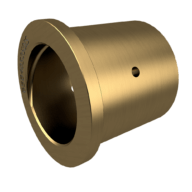

Solid, turned, grinded and hardened steel plain bearing | Requires maintenance

Wrapped spring steel plain bearing | Requires maintenance | DIN 1498 | DIN 1499

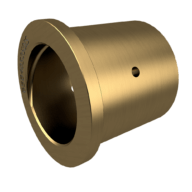

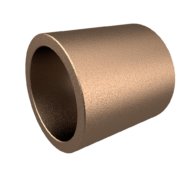

Machined bronze plain bearing | Requires maintenance | DIN 1850 / ISO 4379

Solid bronze plain bearing | Maintenance-free | With solid lubricant deposits in the sliding surface | Version available with water-resistant solid lubricant

Sintered bronze plain bearings | Maintenance-free | Oil-impregnated | Self-lubricating | DIN 1850 / ISO 2795

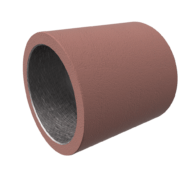

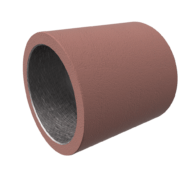

Wound all-plastic plain bearing | Maintenance-free | With a sliding layer of PTFE with lubricant additives

Ready-to-install and maintenance-free sliding support bearing, floating bearing and fixed point

Solid sintered bronze bearing | Maintenance-free | With uniformly embedded solid lubricant in the bronze or iron matrix

Rolled composite plain bearing | Maintenance-free | Steel / graphite bronze | With embedded solid lubricants

Solid, turned, grinded and hardened steel plain bearing | Requires maintenance

Wound all-plastic plain bearing | Maintenance-free | With a sliding layer of PTFE with lubricant additives

Thermoplastic all-plastic plain bearing | Maintenance-free

Fibre-reinforced compound plain bearing in wound technology | Maintenance-free | High load capacity

Machined bronze plain bearing | Requires maintenance | DIN 1850 / ISO 4379

Solid bronze plain bearing | Maintenance-free | With solid lubricant deposits in the sliding surface | Version available with water-resistant solid lubricant

Wrapped composite sliding bearing with lubrication pockets/ CuSn8P & graphite | maintenance-free | DIN 1494 / ISO 3547

Wrapped composite sliding bearing with lubrication pockets/ copper-plated steel & CuSn10Pb10 & graphite | maintenance-free | DIN 1494 / ISO 3547

Wrapped composite sliding bearing steel / Special PTFE coated | Maintenance-free dry sliding bearing | DIN 1494 / ISO 3547

„creating a world of bearing solutions“

Stahlgruberring 26

81829 München - Deutschland

phone: +49 89 4370799-0

fax: +49 89 4370799-44

E-Mail: info@glt-bearings.com

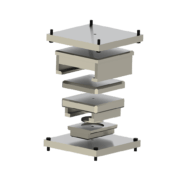

Ready-to-install and maintenance-free sliding support bearing, floating bearing and fixed point

In pipelines, flue gas ducts, steam boilers, heat exchangers, gas filters, etc., thermodynamic expansion movements can occur due to temperature changes, which can usually cause a considerable “accumulation of forces” in a simple steel/steel support.

Due to a primarily jerky “discharge” of these accumulated forces caused by too high friction values of these sliding partners can lead to considerable impairments of the load-bearing construction and the fixed points. In severe cases, this even leads to deformations of the components, up to material cracks.

For a simple, cost-effective and operationally reliable design solution, the use of ready-to-install sliding support and fixed-point bearings is recommended here.

When used with PTFE-coated sliding plates, the sliding support bearings’ excellent sliding and load-bearing properties effectively counteract the problems mentioned earlier. As the sliding support bearings also prevent the “stick-slip” effect, the respective design can be less complex and, therefore, more cost-effective!